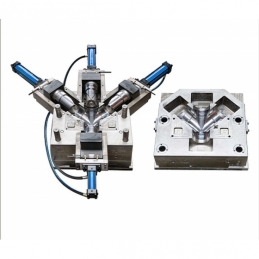

Plastic Injection Molds

Product Details:

| Place of Origin: | CHINA |

|---|---|

| Brand Name: | PLASTAR |

| Model Number: | PIM008 |

| Certification: | CE |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | |

| Delivery Time: | 45DAYS--UP |

| Payment Terms: | T/T OR L/C |

| Supply Ability: | 1000 |

-

Large Image:Plastic Injection Molds

Advantage:

1. Precision customized injection mold for plastic mold.

2. Competitive price

3. Continuance service and support

4. Diversified rich experienced skilled workers

5. Application expertise

6. Quality, reliability and long product life

*Every part is carefully processed (by grinding, machining, milling, wire-cutting, EDM etc) to the exact tolerances shown on the drawing and carefully checked both in production line and QC room (QC check every dimension of every part before packing and shipping).

*we have the capacity to make a wide range of non-standard or customized mold parts and machine parts to meet the growing demands for various industries who are aiming to develop new molds for new products which requires made-to-order service all over the world. We are able to make parts exactly according to customers' drawings or samples.

1. Precision customized injection mold for plastic mold.

2. Competitive price

3. Continuance service and support

4. Diversified rich experienced skilled workers

5. Application expertise

6. Quality, reliability and long product life

*Every part is carefully processed (by grinding, machining, milling, wire-cutting, EDM etc) to the exact tolerances shown on the drawing and carefully checked both in production line and QC room (QC check every dimension of every part before packing and shipping).

*we have the capacity to make a wide range of non-standard or customized mold parts and machine parts to meet the growing demands for various industries who are aiming to develop new molds for new products which requires made-to-order service all over the world. We are able to make parts exactly according to customers' drawings or samples.

PVC pipe fitting mold

1,Cavity and core material--pre-hardened corrosion resistant mirror steel vacuum quenching to HRC46 ° C-51 ° C after process ect.

2.Core slide material -pre -hardened P20 and nitriding to HRC50 ° C -55 ° C after processed , round -square connecting for smooth movement.

3.Cylinder slide -pre-hardened P20 heat treatment to harder with friction resistant lubrication groove, Tee groove introduced between the -beam -shaped board and the base board which is easy to be removed with less deformation.

4.Central inlet and multi-outlet of cooling water make efficient cooling to increase productivity .

5.Gear rack driven by hydraulic cylinders converts near to rotation with sufficient lubrication and no bearing in between

6.The stopper has self-locked structure with friction -proof block YK30;

7.Ejection board has four guides ,bushings centered by the gate which ensures smooth ejection

8.High quality hydraulic cylinders (imported cylinders ) for core pulling devices with Omron limited switches D4N4-4122

9.I-beam-shaped adjustable blocks between the slides and cylinders ;

10.Round inspection window plug can be used either for inspection when it is installed or standard Tee connector when removed

11.Locators are applied between the fixed mold and the moving mold for proper mold clamping .

Product Tag :

plastic injectio molds

Contact Details

Shenzhen Plastar Industry Co.,ltd

Contact Person: Mr SOFIA ZHANG

Tel:0086 136 326 19800

E-mail:sales@china-plastar.com